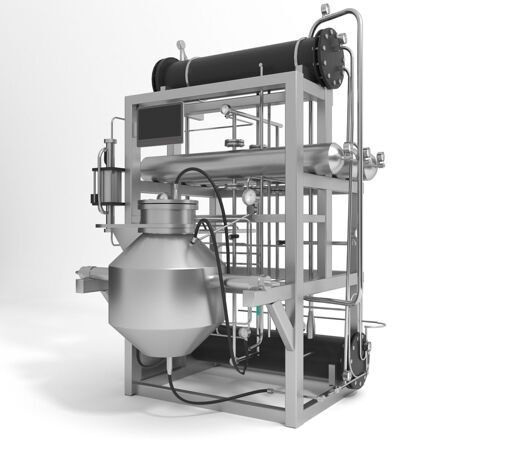

Co2 Extraction System

Subcritical Co2 Extraction System

Subcritical Co2 Extraction System SES 80.

1. General information

- SES 80 - 80 Liters is intended for oil extraction (lipophilic compounds) from plants, fruits, roots and leaves. Oils receive by extraction with use of solvent, liquid dioxide of carbon (СО²). They are absolutely natural and not subjected to thermal processing. These oils use in pharmaceutical industry, in medicine, natural flavoring, additives in the food and cosmetic industry - depending on raw materials. HACCP Certificate (Hazard Analysis and Critical Control Points);

- The system has one extractor and one evaporator;

- The highest working pressure of solid extractor is 7.2 Mpa, the highest working temperature is 9-15°C (48-59°F);

- The design of pressure vessels according the related national standard and rule demand and with over pressure protection system which means enough safety valve – European PED Certificate (Pressure Equipment Directive);

- The whole equipment beauty, safety and easy operation, pressure temperature flow number can be showed from pressure meter and digital instrument. The material of pipe parts, valves, pipe lines, is all stainless steel (AISI304/321).

2. Main technical parameters

a) The highest working pressure: 7.2 Mpa;

b) The operation temperature scope: room temperature: 9-15°C (48-59°F);

c) The flow of CO²: 0~600L/h;

d) The volume of extractor: 80L;

e) The evaporator: 45L volume;

f) Total power: 45KW;

g) Cooling capacity: 25000 Kcal;

h) The power volt: 380V (AC);

i) Installation size: 3.5*2.2*1.9 m.

3. The main configuration and instrument.

3.1 Extractor:

a) Volume: 80L;

b) Amount: 1pc;

c) The max working pressure: 7.2MPa;

d) The max operate temperature: 15°C;

3.2 Evaporator:

a) Volume: 45L;

b) Amount: 1pc;

c) The max operate temperature: 55-75°C;

3.3 Pump* (optional)

(1) Pressure pump

a) Flow: 0~600L/h ( real flow of CO2)

b) The rate working pressure: 40MPa

c) Flow adjustment: 20%—100%

d) Head of pump with cooling structure

3.7. Refrigerating system:

a) Cooling capacity: 25000 Kcal

b) Water cool unit for capacitor.

c) Pressure: 0.2 MPa.

d) Operation temperature (room temperature) ~85°C.

Heat preservation structure, and with stainless shell outside also called jacket water structure).

3.8. The controlling of pressure and temperature:

Pressure control – gauge.

Temperature control – digital sensor.

Using digital meter to show and control precision 1 class.

3.9. Safety system:

It is equipped with a safety valve system.

4. Training content:

1) Safe training of the equipment, including: power, pressure, inflammable and explosive, mechanical drive, health, and so on);

2) Normal operation method and step;

3) Material tank load and unload of extractor;

4) Open and close of extractor;

5) The parameter setting and physics meaning of all controlling component;

6) The operation of high pressure valve control, flow adjustment, temperature setting, pressure balance, and so on;

7) The daily maintenance program and method of this device;

9. Others:

Terms of Payment: T/T 50% of total value as advanced payment, the 50% balance will be paid before shipping.

Delivery Time: 3-4 month from receipt of advanced payment.

Packing: in plywood case.

Quality guarantee:

Three years after installation for main equipment, excluding the wearing and tearing parts.

Validity of the quotation: This quotation is valid for one month.

Installation: We will assemble and test the machine before packing. Also send English manual. If customer need, we will send one engineer for assembling and training of workers. USD150 per person per day, food, accommodation and air-ticket will be on clients.